The Role of Simulation in Heavy Haul Project Planning

Freedom Heavy Haul can offer expedited Pickup and Delivery for any size shipment anywhere in the USA. Contact us today for No Hassle, No Pressure Pricing.

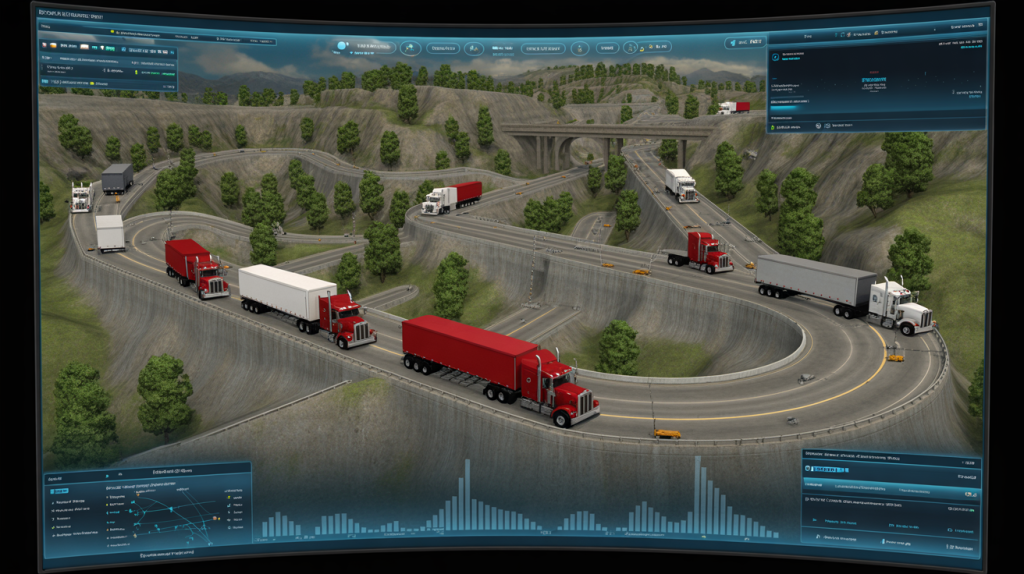

Simulation in heavy haul planning is not about fancy software or “future tech.” It’s about reducing unknowns before a move becomes expensive. When you simulate a heavy haul job, you turn a risky guess into a controlled plan by testing the route, the load behavior, the clearances, the timing, and the decision points, while you still have the freedom to adjust.

At its best, simulation helps a team answer one simple question with confidence: “Will this move work the way we think it will?”

What “simulation” really means in heavy haul

In heavy haul, simulation can be as simple as a structured route walkthrough with measurements, or as advanced as software that models turning radius, grade, axle loading, bridge behavior, and clearance conflicts.

Either way, simulation has the same purpose:

- predict where the move could fail

- identify what must be verified on-site

- choose the safest, smoothest execution plan

- create a repeatable process your team can trust

This connects directly to heavy haul safety management and compliance, because the safest operations are the ones where planning is documented, consistent, and based on verified conditions rather than assumptions.

Why simulation matters more than ever

Heavy haul planning used to rely heavily on experience and “we’ve done this kind of move before.” Experience still matters, but the environment has changed:

- infrastructure is aging in many areas

- construction zones and detours change weekly

- utility conflicts are more common than people expect

- customers want faster delivery, not slower

Simulation helps you keep the speed without sacrificing control.

What you can simulate before the move

1) Route geometry and vehicle behavior

The most practical simulation question is: Can the truck and trailer physically make the turns?

- intersections, roundabouts, and tight access roads

- approach angles into job sites

- off-tracking risk on curves

- low-speed maneuvering zones

This planning becomes sharper when it’s paired with route optimization techniques that consider not only distance but also turning constraints, staging options, and recovery space.

2) Clearance conflicts and “hidden blockers”

Clearances aren’t just bridges. They include:

- overhead lines and low-hanging communication cables

- tree canopies and sign structures

- temporary construction scaffolding and lane control devices

- crowned roads that shift load height during turns

A simulation mindset forces you to label these as “must-confirm” items instead of discovering them at midnight with the load already rolling.

3) Load stability and securement stress points

Simulation helps you anticipate how the cargo will behave when:

- road surfaces change (rough pavement, potholes, gravel)

- braking or lane changes happen at low speed

- wind pushes tall or irregular loads

- grade changes shift weight transfer

That’s why simulation planning should be built on solid securement fundamentals like flatbed securement best practices, and then upgraded with modern securement strategies for oversized cargo when the job requires extra control.

4) Weather and seasonal constraints

Simulation should include a “weather lane,” meaning you plan for what changes if conditions shift.

- extreme heat affects tires, hubs, and braking

- extreme cold affects air systems, traction, and startup reliability

- storms can change safe travel windows and staging choices

For temperature-focused planning, it helps to connect simulation with extreme temperature maintenance preparation, because a plan that ignores equipment behavior in harsh conditions is only half a plan.

5) Risk scenarios and decision points

Simulation is powerful when it includes “if-then” logic:

- If escort arrival is delayed, where do we stage safely?

- If a detour appears, what is the pre-approved alternate?

- If crosswinds exceed a threshold, what is the hold procedure?

- If clearance measurement is borderline, who has authority to stop?

This is where simulation blends into true project discipline, similar to risk management strategy design, because risk control is not just spotting problems, it’s defining what you do next.

A simple simulation workflow heavy haul teams can adopt

Step 1: Build a “move blueprint”

Create a one-page summary that includes:

- load dimensions and weight

- truck/trailer configuration

- axle spacing and target distribution

- start point, end point, and staging points

- permits, escorts, and contacts

Step 2: Run a route simulation pass

Do this before the final permit timing is locked.

- map constraints: turns, grades, construction zones, low bridges

- label clearance risks and mark them “verify”

- choose staging points that allow recovery

Step 3: Simulate the tightest segments first

The job doesn’t fail on the easy highway miles. It fails at:

- city turns

- site access roads

- utility conflict zones

- last-mile obstacles

Plan those segments with the highest attention and treat everything else as support.

Step 4: Run a risk simulation pass

Ask: “Where can this move go wrong in the real world?”

Then define:

- triggers that require stopping

- escalation steps

- alternate path decisions

- communication rules

Step 5: Create an execution checklist

A simulation is only useful if it becomes actions.

- pre-trip confirmation

- measurement checks

- crew briefing sequence

- go/no-go thresholds

- stop routines for inspection and temperature checks

What simulation does for customers, not just search engines

Customers don’t care about the word “simulation.” They care about results:

- fewer delays and fewer surprises

- lower risk of load damage

- clear communication and professional coordination

- confidence that the carrier is prepared

When you explain your planning process on your site, you’re not “writing educational content.” You’re demonstrating competence. That trust is one of the strongest sales signals a service business can show.

Common mistakes teams make with simulation

Treating simulation as optional

Simulation is most valuable on the jobs that feel “almost normal,” because those are the ones where teams relax and miss the one detail that matters.

Simulating only the route, not the operation

A route simulation without a crew plan is incomplete. The move is an operation, not a line on a map.

Skipping reality checks

Simulation should produce a list of items that must be verified on-site. If nothing needs verification, the simulation was too shallow.

Not aligning simulation to standards

Your simulation process should reflect what “safe” means in the industry today. If you want a sharper baseline, the discussion in current heavy haul safety standards helps clarify what responsible operations are expected to do.

Conclusion

Simulation is the bridge between heavy haul experience and heavy haul certainty. It transforms planning from “we think this will work” into “we verified what matters and built a controlled execution.” When simulation is combined with securement discipline, route optimization, equipment readiness, and risk planning, the move becomes smoother for your team and safer for the cargo. And for customers watching from the outside, a company that plans like this doesn’t just look professional, it feels dependable, which is exactly what wins heavy haul projects.