Calculating Optimal Axle Weight Distribution for Heavy Haul Loads

Freedom Heavy Haul can offer expedited Pickup and Delivery for any size shipment anywhere in the USA. Contact us today for No Hassle, No Pressure Pricing.

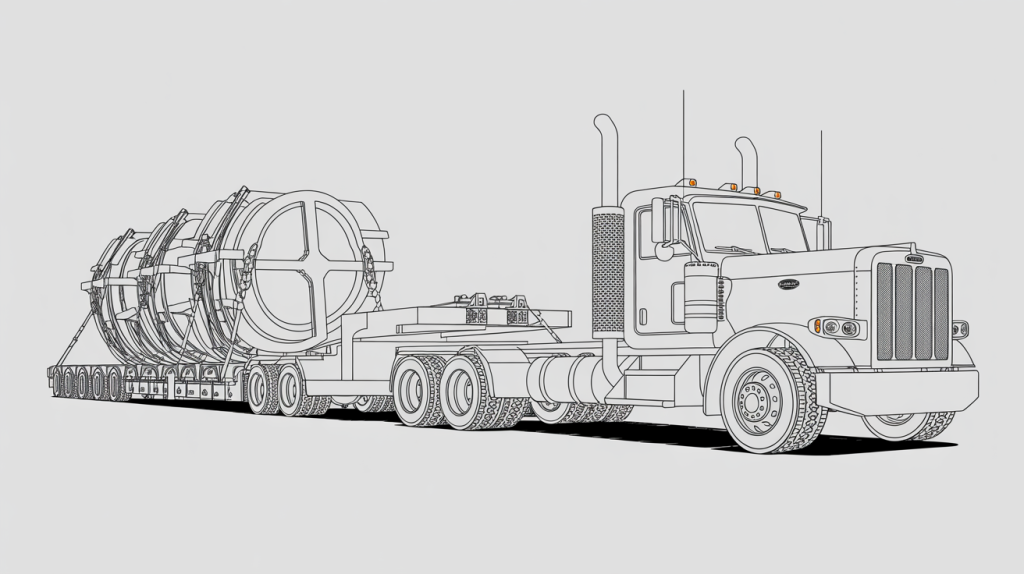

Calculating optimal axle weight distribution is the method of arranging cargo, trailer configuration, and axle groups so that a heavy haul load remains stable, legal, and controllable on the road. Every oversized shipment creates a unique balance challenge. When weight is placed correctly, the truck steers better, brakes more safely, and complies with bridge and roadway limits.

This topic connects directly to the broader process explained in how heavy haul transport projects are planned and executed, because proper weight distribution sits at the heart of successful heavy haul movement.

Why Axle Weight Distribution Matters So Much

A heavy haul vehicle does not behave like a normal truck. The trailer carries extreme loads. The axles share pressure unevenly if the cargo is not positioned carefully. When too much weight rests on a single axle group, tires wear faster, permits can be violated, and braking distances increase.

Balanced distribution keeps three things working together:

- safety for the driver and the public

- protection of roads and bridges

- compliance with state and federal regulations

Without correct weight planning, even a well-permitted route can become unusable.

Understanding How Weight Moves Through a Trailer

Weight on a heavy haul trailer flows in predictable ways. The front of the trailer transfers pressure to the truck. The rear axles absorb the majority of the load. Small shifts in cargo position can change thousands of pounds from one axle group to another.

The key factors that affect distribution include:

- position of the equipment on the deck

- number and spacing of trailer axles

- length of the trailer and neck configuration

- additional attachments such as counterweights or buckets

- road grade and turning angles

Good planning measures these variables before the truck ever arrives at the job site.

Legal Limits Shape Every Decision

Each state enforces limits on how much weight an axle or group of axles can carry. These limits protect pavement and bridges from damage. A load that is technically secure can still be illegal if one axle exceeds its allowable weight.

That is why careful route planning for heavy hauls must be combined with weight calculations. The route and the distribution plan work as one system. A different route may allow a different configuration, and a different configuration may open safer route options.

Practical Steps to Calculate Distribution

The process of calculating distribution follows a clear sequence:

- Identify the exact weight of the cargo

- Measure the center of gravity of the equipment

- Determine trailer axle spacing and capacity

- Position the cargo on the deck for initial balance

- Adjust forward or backward to fine-tune axle loads

- Confirm results with portable scales or engineering tools

These steps transform raw numbers into a real-world loading plan.

The Role of Inspections in Weight Accuracy

Even the best calculations fail if the equipment is not ready. Tires, brakes, and suspension systems must be in proper condition to handle the planned loads. A weak component can change how weight is carried on the road.

Regular pre-trip inspections for heavy haul trucks confirm that the truck and trailer can safely support the calculated distribution. Inspections turn a theoretical plan into a dependable operation.

How Poor Distribution Creates Hidden Hazards

Incorrect axle balance creates problems that may not appear immediately. The truck may feel normal at low speeds but become unstable during turns or emergency braking. Bridges that were cleared during permitting may suddenly be at risk.

These issues overlap with many of the dangers described in identifying potential hazards during heavy haul transportation. Good distribution planning removes a major category of risk before the journey begins.

Special Considerations for Superloads

Extremely heavy shipments require even greater precision. Superloads often involve multi-axle trailers, jeep and dolly combinations, or specialized modular equipment. Small miscalculations on these projects can multiply into serious compliance problems.

In these situations, teams rely on the structured methods outlined in understanding superload transport protocols to confirm that every axle group remains within limits from start to finish.

How Customers Benefit from Proper Weight Planning

For equipment owners and construction companies, optimal axle distribution is more than a technical detail. It directly affects cost, timing, and reliability. When weight is planned correctly:

- permits are approved faster

- detours and re-routes are avoided

- tires and equipment experience less stress

- deliveries arrive without unexpected delays

Balanced loads create smooth projects.

Building a Culture of Weight Awareness

The most reliable heavy haul operations treat axle weight as a continuous responsibility. Drivers, dispatchers, and loaders share the same understanding. Everyone knows that moving an excavator a few inches forward can change the entire profile of a trip.

This mindset protects the truck, the road, and the client’s schedule at the same time.

Conclusion

Calculating optimal axle weight distribution is the practical science that keeps heavy haul transport safe and lawful. When cargo position, trailer design, and route limits are aligned, the load travels with confidence instead of uncertainty. Proper distribution stabilizes equipment, preserves infrastructure, and supports on-time delivery. A well-balanced shipment reflects careful preparation, and careful preparation defines professional heavy haul service.