How Heavy Haul Transport Projects Are Planned and Executed

Freedom Heavy Haul can offer expedited Pickup and Delivery for any size shipment anywhere in the USA. Contact us today for No Hassle, No Pressure Pricing.

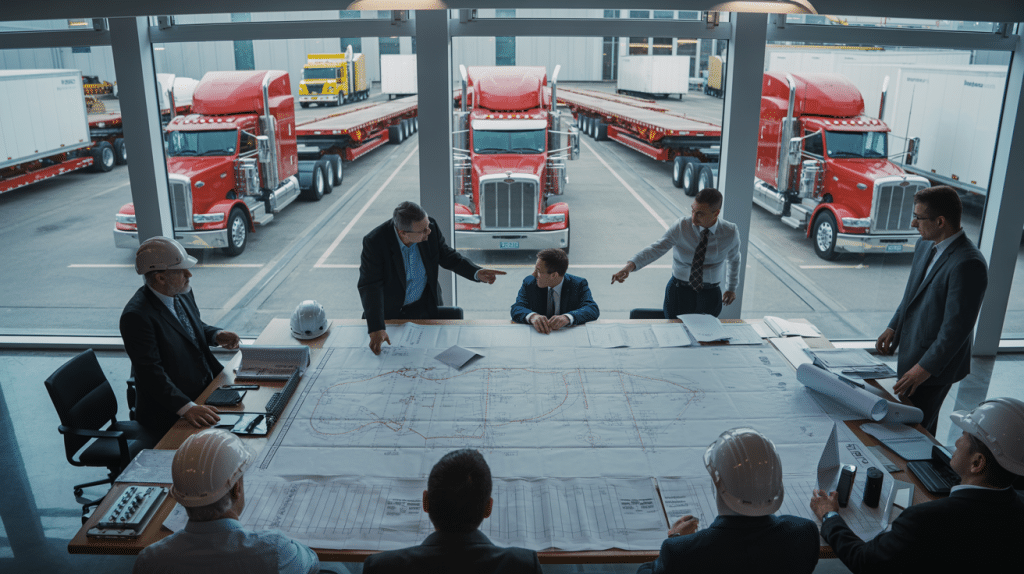

Heavy haul transport is a coordinated logistics process that moves oversized or overweight equipment using specialized trailers, route checks, permits, and safety controls. A move succeeds when the load, the roadway, and the legal requirements all match the plan. When those parts line up, the shipment travels smoothly, timelines stay predictable, and customers feel confident instead of stressed.

What Makes a Load “Heavy Haul”

A shipment becomes heavy haul when size, weight, or configuration goes beyond standard legal limits for typical freight. That shift changes everything. The trip stops being “drive and deliver” and becomes a managed operation where routing, permits, escorts, and securement are planned in advance.

Step 1: Confirm the Details That Control the Entire Move

Every heavy haul plan starts with accurate facts, because permits, trailer choice, and routing depend on them.

Confirm early

- Exact dimensions (length, width, height)

- Total weight and weight distribution

- Equipment condition (drivable, attachments, removable parts)

- Pickup/delivery site access (gates, grades, turning space, soil conditions)

- Timeline constraints (work hours, crane windows, site rules)

When these inputs are correct, the rest of the project becomes measurable and easier to manage.

Step 2: Match the Trailer and Axle Setup to the Cargo

The trailer configuration is the foundation of safety and compliance. A good match improves stability and reduces problems with height, clearance, and axle loading.

Depending on the equipment, the plan may require a step deck, double drop, RGN/lowboy, or a multi-axle setup. The goal is always the same: keep the load balanced, legal where possible, and controllable on real roads.

Step 3: Build the Route Like an Engineered Path, Not a Guess

A heavy haul route is not “whatever Google Maps says.” It’s a verified path that accounts for bridges, clearances, road geometry, and restrictions. This is where route planning for oversized loads becomes the difference between a clean trip and a last-minute shutdown.

Route work typically checks:

- Bridge and roadway weight limits

- Vertical clearances (overpasses, signals, signs, tree canopy)

- Lane width and shoulder stability

- Tight turns, roundabouts, and steep grades

- Construction zones and seasonal restrictions

- Safe pull-offs and staging locations

If the route doesn’t support the load, the plan changes before the truck ever moves.

Step 4: Turn the Plan Into Legal Permission With Permits

Permits are not just paperwork, they define what is allowed, where it is allowed, and when it is allowed. A single shipment can involve multiple jurisdictions, so the permit plan must match the intended route and schedule.

Permits often specify:

- Approved roads and travel windows

- Allowed dimensions and weight

- Escort requirements

- Weather, holiday, or daylight restrictions

When permits are aligned correctly, the move becomes controlled and predictable instead of reactive.

Step 5: Coordinate Escorts, Traffic Control, and Overhead Clearance Issues

As loads get larger, coordination becomes just as important as driving skill. Some routes require pilot cars, law enforcement escorts, or intersection control. Others require advance work with utilities, especially when the load has height concerns. That’s why teams plan overhead utility clearance coordination early, not at the last minute.

This stage often includes:

- Escort scheduling and briefing

- Communication plan between driver, escorts, and dispatch

- Traffic control steps for tight turns or temporary stops

- Clearance actions when overhead lines or signals are in play

Good coordination prevents delays that can snowball into missed site windows.

Step 6: Prepare the Load and Secure It for Real Road Forces

Securement is a safety system. The goal is to prevent movement during braking, turning, bumps, and wind loads. Attachments may need to be removed or locked down. Edges may need protection so chains and straps don’t get damaged. The trailer deck and equipment position must also support stability.

When securement is done right, the trip feels calmer, because the load behaves predictably.

Step 7: Do Pre-Trip Checks That Prevent Expensive Failures

The last step before movement is a full inspection of equipment, paperwork, and readiness. This is where pre-trip inspection discipline protects the project from breakdowns, citations, and forced route changes.

A strong go/no-go check includes:

- Trailer condition (tires, brakes, lights, hydraulics)

- Securement re-check after tension settles

- Permit documents and escort confirmations

- Final clearance checks for tall or wide loads

Small problems caught here save big problems later.

Step 8: Manage Risk During Transit With Active Monitoring

Heavy haul transport is managed throughout the trip, not just dispatched once. Weather can change, work zones can appear, and traffic can compress routes. That’s why experienced teams plan for weather and road condition risks and build realistic contingencies into the schedule.

A managed trip usually includes:

- Continuous communication between driver, escorts, and dispatch

- Planned stops for inspections and securement checks

- Detour strategies and staging points (when needed)

- Updates to the customer when conditions change

This is how you keep the project stable even when the environment changes.

Step 9: Identify Hazards Before They Become Emergencies

Heavy haul hazards often show up in predictable places: low clearances, weak shoulders, unexpected detours, tight turns, steep grades, or local restrictions. Planning works best when the team treats risk as something to map, not something to “deal with later.” That’s why crews use hazard identification planning as part of the route and execution process.

When hazards are anticipated, the move stays controlled and the public stays safe.

Step 10: Keep the Move Responsible Around Communities and Job Sites

Heavy haul transport happens in the real world, near neighborhoods, businesses, and active job sites. Smart planning reduces disruption by controlling timing, avoiding sensitive corridors when possible, and using spotters or escorts where needed. This is where reducing community impact becomes both a safety advantage and a reputation advantage.

Customers also benefit, because fewer disruptions usually mean fewer delays.

Step 11: Balance Axle Loads for Compliance and Stability

Many heavy haul problems come down to how weight is distributed. Axle loading impacts permits, bridge compliance, braking performance, and overall stability. Teams that understand optimal axle weight distribution can often simplify the move, reduce risk, and avoid permit complications.

This is one of the most “quietly important” parts of planning, and it’s where experienced carriers separate themselves.

Step 12: Know When a Shipment Becomes a Superload

Some shipments exceed normal oversize/overweight thresholds and require special approvals, advanced escort requirements, route engineering, and broader coordination. These moves follow stricter rules and tighter planning windows, which is why superload transport protocols must be handled deliberately.

When this is planned correctly, even extremely large loads can move safely and legally.

Conclusion

A heavy haul project succeeds when it is planned as a complete system: accurate load details guide trailer selection, trailer selection shapes axle loading, axle loading influences permits, permits define routing, and routing drives coordination for escorts, utilities, safety, and timing.

This end-to-end approach helps search engines understand that the site covers the full heavy haul process, and it helps equipment owners and construction teams trust the guidance because it reflects how real projects are executed. When the gaps are filled with the right supporting topics, the site becomes more useful, more credible, and more competitive, because completeness wins in modern search.